|

|

Corn stalk continuous carbonizing furnace

收藏

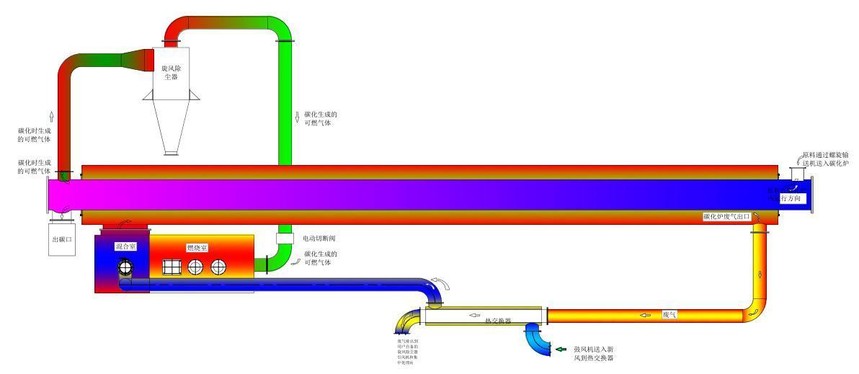

The biomass continuous carbonization furnace is an environmental protection and energy saving product independently developed by our company. Suitable for the carbonization treatment of wood and fiber based garden waste raw materials, crop straw raw materials, waste wood chips (wood), bamboo chips, wood chips, various fruit shells. Equipment highlights: In terms of environmental protection, the whole carbonization process of the equipment can achieve no tar, no sewage discharge, no black smoke discharge. Applicable biomass raw materials: crop straw, various garden wastes, waste bamboo, wood chips and other biomass raw materials. The carbon produced after carbonization of different raw materials can be used in civil carbon, industrial carbon and carbon based fertilizer production and activated carbon preparation and other different industries. Carbon-based fertilizer: straw carbon or carbon-based organic fertilizer, and other fertilizers can be made into carbon-based mixed hefei, increase fertility. Carbon-based agriculture: can be used as soil improver to improve fruit and vegetable yield and quality. The biomass produced can be gas: converted into heat energy is widely used in hot water boilers, industrial boilers, agricultural heating and so on. I. Technical parameters of continuous biomass carbonization furnace

二Advantages of carbonization equipment ● Continuous productivity: raw materials from feeding to carbonization can be 24 hours a day uninterrupted operation, stable production, continuous operation of carbonization. ● Less transmission parts, low power demand. Low investment cost, low management cost, quick recovery. ● Good resource recovery effect: materials can be according to user needs, using different temperature control carbonization process, to ensure that different raw materials carbonization to achieve different carbonization effect. ● Strong application ability of the equipment: it can adjust the material speed according to the actual needs, PLC control, flexible and convenient operation. ● High safety performance: PLC centralized control, specific parameter setting, detection and display, chain protection, failure alarm and other functions. Three, agricultural and forest waste carbonization process

Applicable biomass raw materials: crop straw scraps, a variety of garden waste tree branches, reed bamboo, wood chips and other biomass energy. The carbon produced after the carbonization of agricultural and forestry wastes is widely used in industrial carbon, civil carbon, carbon fertilizer production and activated carbon preparation and other industries. Carbon-based fertilizer: straw carbon or carbon-based organic fertilizer, and other fertilizer raw materials can be made into carbon-based mixed hefei, increase fertility. Carbon-based agriculture: can be used as soil improver to improve fruit and vegetable yield and quality. Produced gas: carbonized from its own production and supply, excess heat energy can be used as auxiliary heating. Four, advantages of carbonization equipment: ● Continuous productivity: raw materials from feeding to carbonization can be 24 hours a day uninterrupted operation, stable production, continuous operation of carbonization. Furnace sealing, no oxygen into the furnace to prevent the material burning in the carbonization furnace. ● Less transmission parts, low power demand. Small footprint and low investment cost. ● Good resource recovery effect: materials using medium temperature carbonization process, to ensure better raw material carbonization effect. ● Strong application ability of the equipment: it can adjust the material speed according to the actual needs, PLC control, flexible and convenient operation. ● High safety performance: PLC centralized control, specific parameter setting, temperature, pressure display, failure alarm and other functions. Product picture:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||